Many tobacco consumers don’t think about how cigarettes are made or what elements they are made of. This article will examine in detail the main components of a cigarette, as well as discuss current trends in cigarette production and alternative methods of tobacco consumption.

Contents

Origin. Tobacco, also known as Nicotiana tabacum, originally appeared in the Americas. Its use began over five thousand years ago. Indigenous peoples used it in rituals. Tobacco was an important part of Native American culture, smoking it in pipes or chewing it.

Spread in Europe. With the discovery of America in 1492, tobacco arrived in Europe. Tobacco production quickly became popular in Europe. Smoking was primarily available to the aristocracy due to the high cost and limited availability of tobacco.

Spread of smoking habits. Tobacco was used not only for smoking but also for chewing. The first cigarettes appeared as early as the 17th century, initially hand-made, and later, the first tobacco processing factories appeared. By the end of the 18th century, cigarette smoking had become widespread.

Mass Production. In the 19th century, smoking became widespread among all social classes. The mass production of factory-made cigarettes in the early 20th century made cigarettes affordable. New technologies, including automated cigarette-making machines, significantly increased production volumes.

Modern Trends. The tobacco industry has changed significantly in recent decades: manufacturers regularly introduce technological innovations. Companies create cigarettes in various formats and types, including classic cigarettes with flavored additives and capsule cigarettes, and are also developing new categories, such as heated tobacco systems. Meanwhile, legislation on cigarette production and sales is becoming stricter worldwide, with restrictions varying from country to country.

1. Selecting Tobacco. The process begins with the selection of raw materials. This stage is crucial, as tobacco is the foundation of cigarette quality. Manufacturers strive to select reliable, proven suppliers and work with farms in tobacco-growing regions around the world. Every detail is important when growing tobacco—from soil, fertilizer, and irrigation to the right climate and the right time of harvest. There are different varieties of tobacco, each with its own flavor and aroma. You can read more about this here.

2. Drying. After harvesting, the tobacco leaves must be dried. They can be dried outdoors in the sun, in special dryers, or over an open fire (fire drying). Drying helps preserve the flavor and aroma, add specific notes, and prevents rotting.

3. Fermentation. The dried leaves undergo fermentation, which improves the flavor and aroma of the tobacco. The leaves are folded and moistened. Fermentation lasts from several weeks to several months.

4. Cutting. After fermentation, the leaves are cut. This is done on special machines that ensure a uniform cut. The size of the cut determines how the cigarette burns and its flavor.

5. Blending. The cut tobacco is blended. Manufacturers create unique blends by combining different varieties and types of tobacco. This allows them to achieve the desired flavor, aroma, and richness. This blend is called a tobacco blend. One of the most common is the so-called “American” blend.

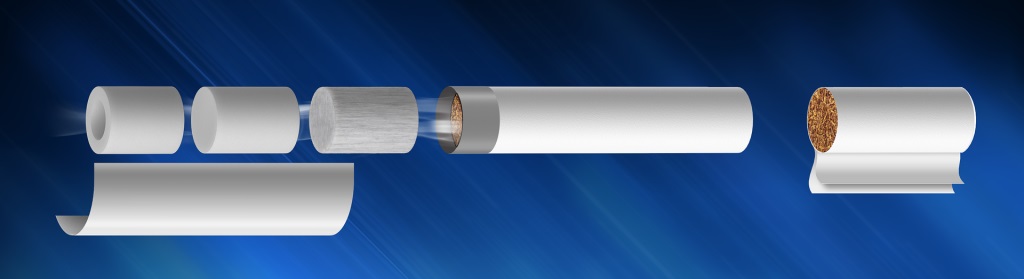

6. Forming. The blended tobacco is placed in automatic machines. They form the cigarettes: they fill them with tobacco and wrap them in special cigarette paper.

7. Packaging. The finished cigarettes are packaged in packs of 20. The packaging includes the name of the tobacco product, a warning about the dangers of tobacco consumption, information about the manufacturer, and other required information in accordance with national legislation.

8. Distribution. Packaged products are shipped to stores and other retail outlets. Manufacturers also work with distributors to ensure product delivery to retail outlets.

Let’s take a closer look at the components of a cigarette.

The first and most important element is the tobacco, or tobacco blend, which varies depending on the manufacturer and product type.

Typically, the tobacco blend includes various varieties, such as Virginia, Burley, and Oriental. These varieties are blended in specific proportions to achieve the desired flavor and nicotine intensity. For example, Virginia is known for its sweet taste, while Burley has a richer aroma.

Tobacco can be infused with special additives (flavorings) such as berry, menthol, or even exotic flavors. This diversity helps create cigarettes that satisfy the varying preferences of smokers. For example, some prefer a sweeter flavor, while others prefer a more tobacco-infused, richer aroma. You can learn more about tobacco blends in our other article.

The next essential component is rolling papers. This is a special product in cigarettes that wraps the raw materials. Cigarette paper is made from cellulose.

High-quality cigarette paper is dense and porous, ensuring an even burn. Sometimes substances are added to the paper to alter the burn rate and smoke flavor.

Cigarette paper is usually white, but can also come in various textures and colors. For example, brown cigarette paper with a kraft texture is often used for flavored cigarettes. Some manufacturers also use special printing technologies to add unique designs to the tipping paper.

The filter is another important element that must be present in a modern cigarette. The filter prevents tobacco from entering the oral cavity. It can be made of various materials, such as cellulose acetate or activated carbon, and can also consist of several parts. Sometimes the filter is coated with a special coating with a sweet flavor to enhance or complement the cigarette’s aroma.

There are several types of filters, including:

- Basic filters: made from cellulose acetate fibers, these are the most commonly found on the market.

- Carbon filters: These get their name from the additional element they contain—in addition to the standard components, they also contain activated carbon.

- Three-compartment filters: made from several sections, such as an air chamber (a dense section with a hole inside), a monoacetate section, and a carbon filter.

- Capsule filters: one section of a standard filter contains a capsule containing a flavoring agent, which can be popped to release additional flavor. Simply press on the filter, and the capsule will burst, releasing the flavoring agent into the smoke.

Tipping paper connects the filter to the rest of the cigarette. It is also made of cellulose. It is also very durable, allowing the cigarette parts to seal tightly. This paper helps cigarettes break less often and last longer in the pack and in your hands. Furthermore, tipping paper is also available in various textures and colors, such as gold or silver.

Conclusion

The main components of a cigarette are paper, tobacco blend, and filter. Despite its apparent simplicity, it’s worth noting that the correct combination of all components creates a high-quality final product.